Chambar Sugar Mills, a prominent entity within the sugar industry, began its operations in 2011. This mill, formerly known as Bachani Sugar Mills Ltd., was acquired by the Omni Group in May 2011. Situated strategically at Deh: Chuch, Union Council Chambar 2, Taluka: Chambar, District: Tando Allayar, Sindh, the mill is located just 14 kilometers away from Tando Allayar Sugar Mills (Pvt.) Ltd., playing a vital role in the regional sugar production landscape.

The majority of the sugar processing equipment at Chambar Sugar Mills was procured from Heavy Mechanical Complex (HMC). The facility boasts a comprehensive array of processing equipment, including two Boiler Houses, a Power House, a Process House, and a Mill House. The equipment for the Power House was imported from Peter Brotherhood, England, ensuring robust and reliable power generation capabilities. Additionally, the turbines and refining machines were sourced from Broad Bent Centrifugal Machines, England, underscoring the mill’s commitment to quality and efficiency.

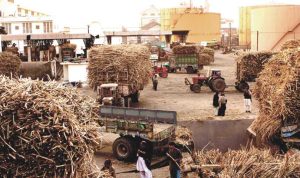

Chambar Sugar Mills operates with a crushing capacity of 5,000 tons of cane per day (TCD). The mill produces a variety of products including white refined sugar, molasses, bagasse, and pressmud. The white refined sugar produced is of R1 grade, adhering to high-quality standards.

Employment Generation

One of the most immediate and visible impacts of Chambar Sugar Mills is its contribution to employment. The mill provides direct employment to a substantial number of workers, ranging from skilled technicians to unskilled laborers.

Direct Employment:

- Factory Workers: The mill employs hundreds of individuals in various capacities, including machine operators, quality control analysts, and administrative staff.

- Seasonal Workers: During the harvesting and processing seasons, there is a significant influx of seasonal laborers who find temporary employment, thus boosting their incomes during critical periods.

Indirect Employment:

- Supply Chain Jobs: Numerous jobs are created indirectly through the supply chain. These include roles in transportation, warehousing, and distribution networks.

- Ancillary Services: Local businesses such as food vendors, retail shops, and repair services thrive on the demand generated by the mill workers and their families.

Agricultural Development

Chambar Sugar Mills plays a pivotal role in the development of agriculture in the region, particularly concerning sugarcane cultivation.

Enhanced Agricultural Practices:

- Training Programs: The mill offers training programs for local farmers, introducing them to modern agricultural practices and technologies that increase crop yields.

- Quality Inputs: By providing high-quality seeds, fertilizers, and pesticides at subsidized rates, the mill helps farmers improve the quality and quantity of their produce.

Financial Support:

- Credit Facilities: The mill often extends credit facilities to farmers, enabling them to invest in better farming equipment and inputs.

- Guaranteed Purchase: With a guaranteed purchase agreement for their sugarcane, farmers experience reduced market risk and increased financial stability.