Khoski Sugar Mills, located in the heart of Pakistan’s cane-growing region, has been producing high-quality sugar since 2011. With a crushing capacity of 4,500 TCD and a workforce of over 800 employees, the company has established itself as a leading player in the sugar industry. In this article, we will delve into the sugar production process at Khoski Sugar Mills, highlighting the key steps involved in transforming sugarcane into white refined sugar.

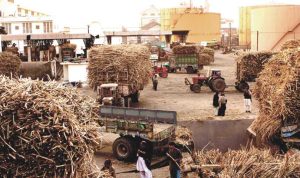

Step 1: Cane Reception and Handling

The journey begins with the receipt of sugarcane from local farmers. The cane is unloaded and weighed, and then transported to the mill house for processing.

Step 2: Juice Extraction

The sugarcane is fed into the mill house, where it is crushed to extract the juice. The juice is then transferred to the process house for further processing.

Step 3: Clarification

In the process house, the juice is mixed with lime and heated to remove impurities. The mixture is then passed through a series of filters to produce a clear juice.

Step 4: Evaporation

The clear juice is then transferred to the evaporation station, where it is heated to remove excess water. This process produces a thick, syrupy liquid called concentrate.

Step 5: Crystallization

The concentrate is then transferred to the crystallization station, where it is seeded with sugar crystals. The mixture is then left to cool and crystallize, producing a mixture of sugar crystals and molasses.

Step 6: Centrifugation

The sugar crystal mixture is then passed through a centrifuge to separate the sugar crystals from the molasses.

Step 7: Drying and Packaging

The sugar crystals are then dried and packaged as white refined sugar, ready for distribution.

By-Products

In addition to white refined sugar, Khoski Sugar Mills also produces molasses, bagasse, and pressmud as by-products. These products are used in various industries, including animal feed, biofuel, and construction.

Conclusion

Khoski Sugar Mills’ sugar production process is a testament to the company’s commitment to quality and efficiency. With its state-of-the-art equipment and skilled workforce, the company has established itself as a leader in Pakistan’s sugar industry. By understanding the sugar production process, we can appreciate the hard work and dedication that goes into producing the sugar we use every day.