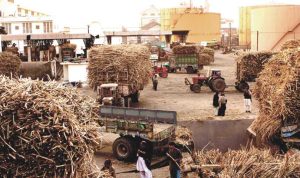

Located in the heart of District Tando Allayar, Sindh, Tando Allayar Sugar Mills commenced its operations in 2012, marking a significant milestone in the region’s sugar industry. Boasting a strategic location chosen meticulously based on extensive analysis of sugarcane yield and sucrose recovery rates, the mill swiftly achieved its commercial operation date on January 27, 2012, following its commissioning.

Equipped with cutting-edge technology, the plant stands as a testament to innovation and efficiency in sugar processing. A substantial portion of its processing equipment, including 02 Boiler Houses, Power House, Process House, and Mill House, originates from Heavy Mechanical Complex (HMC), ensuring reliability and quality in operations. Furthermore, the mill is powered by 12 MW Mill turbines imported from Sojitz, Japan, enhancing its capacity for efficient production. Refining machines, vital for ensuring high-quality sugar products, are sourced from TSK, underlining the commitment to excellence in every aspect of production.

Understanding Regulatory Landscape:

Before delving into specific challenges, it’s essential to grasp the diverse regulatory framework governing Tando Allayar Sugar Mills. These regulations span a wide array of domains, including environmental, safety, labor, and quality standards. Compliance with these regulations ensures not only legal adherence but also promotes sustainable and ethical business practices.

Environmental Compliance:

One of the foremost challenges faced by Tando Allayar Sugar Mills revolves around environmental compliance. Sugar mills, by their very nature, are resource-intensive and can have significant environmental impacts if not managed carefully. Compliance with emissions standards, wastewater treatment, and solid waste disposal regulations are critical concerns for the company.

Air Emissions:

Emissions from the combustion of bagasse, a byproduct of sugar cane processing, pose challenges in meeting air quality standards. Implementing efficient combustion technologies and regular maintenance of equipment are crucial strategies employed to mitigate air pollution.

Wastewater Management:

The sugar extraction process generates substantial volumes of wastewater containing organic matter and chemicals. Compliance with effluent standards necessitates the implementation of robust wastewater treatment systems, including sedimentation, filtration, and biological treatment processes.

Solid Waste Disposal:

The disposal of solid waste, such as bagasse residue and filter cake, requires adherence to regulations governing landfill operations and recycling practices. Tando Allayar Sugar Mills emphasizes recycling initiatives to minimize waste generation and maximize resource utilization.

Labor Regulations:

Ensuring compliance with labor laws is another significant challenge faced by Tando Allayar Sugar Mills. The labor-intensive nature of sugar cane cultivation and processing necessitates adherence to regulations governing working conditions, wages, and occupational safety.

Working Conditions:

Providing safe and healthy working conditions for employees is a top priority for the company. Compliance with regulations regarding workplace safety, hygiene, and ergonomics is enforced through regular inspections and employee training programs.

Wages and Benefits:

Fair compensation and benefits are essential for maintaining a motivated and productive workforce. Tando Allayar Sugar Mills adheres to minimum wage laws and offers additional benefits such as healthcare coverage and social security contributions to its employees.

Occupational Safety:

The operation of heavy machinery and exposure to hazardous chemicals pose risks to employee safety. Compliance with safety regulations involves the implementation of safety protocols, provision of personal protective equipment, and conducting regular safety audits.

Quality Standards:

Maintaining product quality and safety standards is imperative for Tando Allayar Sugar Mills to remain competitive in the market and ensure consumer satisfaction. Compliance with food safety regulations and quality control measures is integral to its operations.

Food Safety:

Sugar production involves processes that directly impact food safety. Adherence to food safety standards, such as Hazard Analysis and Critical Control Points (HACCP), ensures the production of safe and hygienic sugar products for consumers.

Quality Control:

Stringent quality control measures are implemented throughout the production process to monitor and maintain product quality. Regular sampling, testing, and analysis of raw materials and finished products are conducted to meet regulatory requirements and customer expectations.

Strategies for Compliance:

Addressing the myriad of compliance challenges requires a proactive and holistic approach from Tando Allayar Sugar Mills. The company employs a range of strategies to ensure adherence to regulations while promoting sustainable and responsible business practices.

Investment in Technology:

Continuous investment in state-of-the-art technology and equipment enables Tando Allayar Sugar Mills to enhance operational efficiency and meet regulatory standards effectively. Advanced pollution control systems, wastewater treatment plants, and quality monitoring equipment are integral components of its infrastructure.

Employee Training and Engagement:

Empowering employees with the knowledge and skills necessary to comply with regulations is essential. Tando Allayar Sugar Mills conducts regular training sessions and workshops to educate employees on safety protocols, environmental conservation, and quality control measures.

Stakeholder Collaboration:

Collaboration with regulatory authorities, industry associations, and local communities fosters a conducive regulatory environment. Tando Allayar Sugar Mills actively engages with stakeholders to exchange best practices, address concerns, and contribute to the development of regulatory policies.

Continuous Improvement:

Adopting a culture of continuous improvement enables Tando Allayar Sugar Mills to stay abreast of evolving regulatory requirements and industry standards. Regular internal audits, performance evaluations, and feedback mechanisms drive innovation and compliance excellence within the organization.